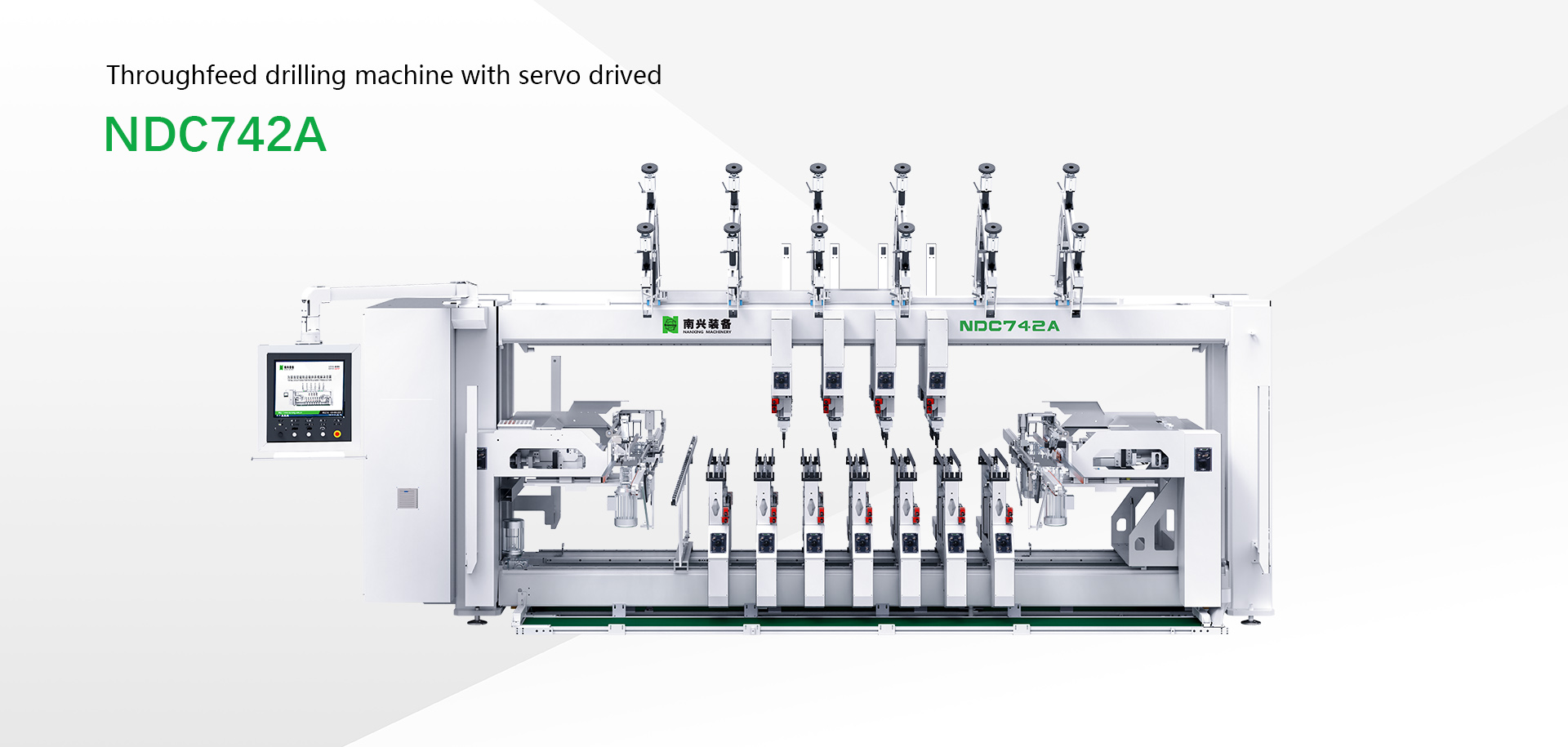

Through-feed Drilling By Servo NDC742A

-

Auto 12 Rows Boring Machine is recommended to use for mass production even with frequent adjustments of boring hole patterns from time to time by furniture companies. Movement of vertical boring rows is easy, fast and precise by servo motor corresponding to rack and pinion. IPC controlled, vertical rows move automatically on the basis of hole position drawings thus the machine is easy to set in production line.

-

Pneumatic locking device applied at vertical rows, for adjusting or changing of drilling block much faster and precise; Boring blocks with this flexibility can make different boring hole pattern easy.

-

6 rows on bottom, 4 top rows and 2 rows on side make it possible to boring 4 sides in one process, up to 22pcs work pieces per minute.

-

+91 99803 91827+91 99803 91827

-

info@nanxingindia.cominfo@nanxingindia.com

Technical Data

|

Model |

NDC742A |

|

Max panel width |

2550 mm |

|

Min. panel width |

250 mm |

|

Max. panel thickness |

50mm |

|

Max feeding speed |

78m/min |

|

Vertical drills qty. |

4 rows*11*2=88 |

|

Horizontal drills qty. |

2 rows *21=42 |

|

32mm |

|

|

Servo motor qty. |

7 |

|

Max vertical boring depth |

45mm |

|

Max horizontal boring depth |

40mm |

|

Total power |

62Kw |

|

Approx. weight |

7600 kg |

|

Overall dimension |

5,540*3,660*2350 mm |